On 2018-08-08 14:48:54

2018 Heat Treatment International Specialized Exhibition on Technologies and Equ

On 2018-08-08 11:45:46

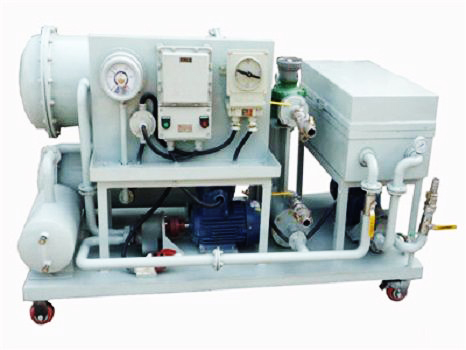

vacuum oil filter installation

1. All parts of the oil filter have been adjusted and tested before leaving the factory, and all parts should be checked to see if they are in good condition when transported to the site of use.

2. The vacuum oil filter is placed smoothly, the oil inlet is connected to the oil outlet at the lower part of the oil tank, and the oil outlet is connected to the upper part of the oil tank.

3. After long-distance transportation, it is necessary to re-tighten the connection parts of all parts, such as connection flange and filter cover plate.

4. The external wiring of the control panel is shown in the wiring diagram of the electric appliance. Connect the 380V three-phase four-wire alternating current from the lower left side hole of the electric control cabinet. The control cabinet shell should be reliably grounded. The power distribution cabinet and the connection of oil pump, vacuum pump and heater should be checked to ensure the connection is firm and the insulation is reliable.

5. Close the main power switch and check whether the power indicator is on. If not, check and troubleshoot according to the circuit diagram

6. Click the start/stop button of the vacuum pump for 2-3 times, and observe whether the motor rotates clockwise (facing directly from the motor end). A motor rotation arrow is marked on the motor. The same method is used to test the running direction of the oil pump motor. And check the vacuum pump - motor, oil pump - motor whether stuck resistance phenomenon.

7. Close all the unit connected to the air valve (except cut-off valve) in and out of the tubing is connected, ensure smooth import and export oil tank to the machine, start the vacuum pump, when the vacuum degree reaches 0.08 MPA, close vacuum pump, vacuum watch 5 minutes table value, if the vacuum value falling too fast, that has funnelled, find out funnelled, until completely without funnelled machine.

8. Check whether the temperature controller is interlocked with the heater, that is, the heater controlled by the temperature controller can only be completed in an instant.

9. When the hydraulic oil and other mechanical oil are processed online, the same brand of oil shall be properly supplemented to ensure the normal oil level of the oil tank.

vacuum oil filter steps

1. Connect the oil filter with the power supply, connect the oil inlet and outlet pipelines, and close the valves required in the instruction according to the flow chart.

2. Start the vacuum pump. When the vacuum degree reaches -0.08mpa, open the oil inlet valve and the oil outlet valve, so that the oil will gradually flow into the oil filter.

3. Observe the oil spraying in the vacuum separator through the visual window. The oil will be sprayed into the vacuum separator after filling the heater, the primary filter and the water distributor. (note: before the oil pump starts, the oil valve must be opened, otherwise it is easy to cause the risk of pipe explosion.)

4, if the inlet and outlet oil is not balanced, the inlet and outlet oil valve can be adjusted to achieve the inlet and outlet oil balance. For example, if the oil pumping speed is too fast, the oil valve can be properly closed to reduce the amount of oil, so as to achieve the balance of oil in and out. For example, before heating, the viscosity of cold oil is too large, resulting in less oil intake, pressure index rise, can be used to open the bypass valve (but not more than a third of the Angle), to achieve the oil balance.

5. Turn ON the heater "off-on heater" when the oil is filtered through the oil filter in a normal circulation (that is, when the amount of oil in and out reaches a balance). The temperature controller is set between 45 ℃ and 70℃ (as required), and the oil is heated at constant temperature to ensure the normal degassing and dehydration of the vacuum separator.

6. In the early stage of oil filtration, the oil is easy to form foam in the vacuum separator, and the vent valve can be opened appropriately for defoaming.

7. When the oil filter works normally, the filtered water vapor and gas are cooled and precipitated in the water reservoir in the cooler.

8. Drain the water from the storage tank until the water is drained. After a period of operation, samples can be taken and analyzed at the oil valve of the filter.