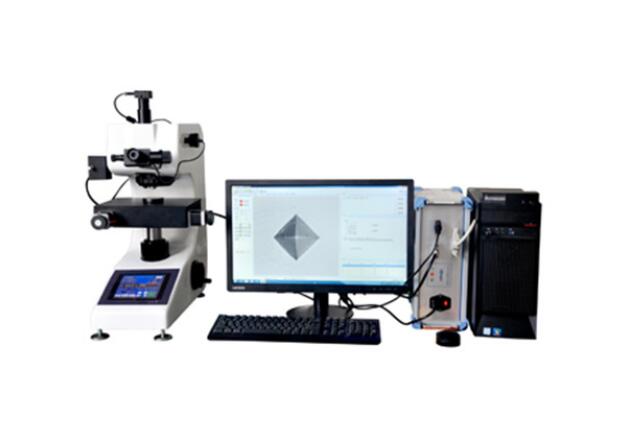

microhardness tester of metals

The digital micro hardness tester can meet the basic Vickers hardness test requirements. The upgraded digital micrometer can directly read the measurement length, so that the measured value can be obtained more quickly and accurately. The LCD large-screen display is convenient for observation, test conditions, and the test process is straightforward. This machine is equipped with a micro hardness tester system: it can be used for continuous test of continuous indentation after continuous loading, and can carry out successive experiments for each load and each indentation. Using a digital camera with a convenient ccd camera, video cable, or USB interface, the measurement indentation can be directly observed on the monitor, and the accuracy can be measured with the mouse. For setting test conditions, displaying results, etc. can be operated and displayed clearly and quickly. Through the measurement software, it can be easily operated by a computer. A single point measurement can be used to randomly measure multiple points and statistical measurement data, and the distance between two or more measurement points can be arbitrarily set as a depth measurement of the penetration layer. Measurements can be made along X or Y directions. , Statistical measurement data, according to the user input automatically determine the depth of hardened layer calculations. Statistics calculations, conversion, display curves, to determine whether the qualified. Can measure the length of the part of graphics preservation and printing.

Software features:

1. Universal USB controls, can be used with a USB camera, support more than 90% USB camera on the market, including chat camera, no capture card, notebook can also be used to save costs (also have a capture card version, the price is not the same , faster response, more stable, more powerful);

2. Carburized layer depth analysis, detailed report;

3. 10, 20, 40, 3 kinds of magnifications can be switched freely, and can be separated without affecting each other;

4. Replacement force without recalibration;

5. 14 kinds of E140 standard scale conversion;

6. Can achieve automatic measurement;

7. magnifier function, measurement easier;

8. The force value can be freely set, there is no limit of magnification, override software calibration, theoretically can measure all Vickers including small load;

9. Exclusive features: a hardness block to complete the calibration, eliminating the need for high-price multiplier, more convenient, easier and more accurate.

Main functions and features:

1. The optical system designed by senior optical engineers not only has clear images, but also can be used as a simple microscope. The brightness is adjustable, and it is visually comfortable. Long-time operation is not easy to fatigue.

2. The industrial display screen can directly display the hardness value, the conversion hardness, the test method, the test force, the retention time, the number of measurements, and the test process is intuitive and clear;

3. Cast aluminum shell molding, structural stability is not deformed, pure white car paint high grade, anti-scratch ability, use for many years is still bright as new;

4. Our company has its own R&D, production and processing capabilities. Our machines provide parts replacement and maintenance upgrade services for life.

5. HVS-1000 models can be directly measured by the actual measurement of the length to obtain the hardness value.

Technical Parameters:

Parametername | Parameter data |

Micro hardness scale | HV0.01,HV0.025,HV0.05,HV0.1,HV0.2,HV0.3,HV0.5,HV1 |

Display | Holding time (seconds), hardness value |

Test force (gf) | 10,25,50,100,200,300,500,1000 |

Loading control | Automatic (load/hold/uninstall) |

Test force retention time (s) | 5 to 60 |

Test force selection | External selector knob, test force is automatically displayed on the LCD screen |

Objective magnification | 10×, 40× |

Optical channel | Dual light channels (eyepieces and CCD camera channels) |

Optical system | 1. Automatic digital encoder; |

Hardness measurement range | (5-3000) HV |

XY test platform | Size (mm): 100×100 |

Maximum height of specimen (mm) | 110 |

Maximum width of specimen (mm) | 85(distance from the center line of the indenter to the wall) |

Voltage | AC220V/50HZ |

Weight (kg) | 35 |

Dimensions | (540×200×530)mm |

Standard configuration:

1. Host ( Micro Vickers indenter x1, 10x objective x1, 40x objective x1) | 2. Test platform, weight, microscope accessory box; |

3. Weights x6 | 4. Weight bar x1 |

5. Cross table x1 | 6. Sheet clamping table x1 |

7. Flat mouth clamping table x1 | 8. Filament holding table x1 |

9. Level meter x1 | 10. Screwdriver x2 |

11. Horizontal adjustment screws x4 | 12. External power cord x1 |

13.10× Digital Micrometer Eyepieces x1 | 14. Micro Vickers hardness block x2 (HV1, HV0.2 x1 for each ) |

15. Fuses (1 A) x2 | 16. Product certification x1 |

17. Product Instruction Manual x1 | 18. Dust cover x1 |