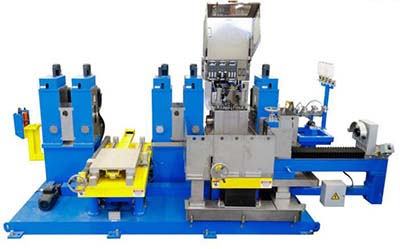

Quick Forging Testing Equipment

Performance features:

YQ series unqualified testing machine is designed according to the international standard metal material unqualified test method, which is especially suitable for the quality inspection of high-speed bar and wire rod. By simulating the rapid impact of the metal materials in the forging and pressing process, the machine truly reflects the situation of the rapidly compressed bars and wires. Under the condition of room temperature or heating, apply the test force along the axis direction of the specimen, compress the specimen rapidly, and then check the forging deformation ability of the metal bearing according to the specified forging ratio. It can also show the deformation of the metal surface. It is widely used in iron and steel industry, standard sample manufacturing industry and tool manufacturing industry to check the unqualified test of metal materials.

Application scope:

Metal bar, wire;

Fasteners, standard parts, tools;

Applicable standards:

YQ series is designed according to the international standard "test method for unqualified metal materials".

Specifications:

Model and Specification | YQ-3000 | YQ-5000 |

Max Upset Force(kN) | 3000 | 5000 |

Max Shearing Force(kN) | Optional:1000kN | |

Max Alignment Force(kN) | Optional:150kN/300kN/600kN | |

Cold Upset Speed(mm/s) | 60 | 70 |

Hot Upset Speed(mm/s) | 90 | |

Upset Time(s) | 0.5 | |

Specimen for Shearing(mm) | / | |

Speimen for Cold Upset(mm) | 18-35 | 20-45 |

Speimen for Hot Upset(mm) | 20-90 | 20-110 |

Cold Upset Ratio | 1/2 | |

Hot Upset Ratio | 1/3 | |

Dimension of Load Frame(mm) | 750*750*1905 | 1100*1100*2250 |

Dimensions of Hydraulic Power Unit(mm) | 1800*1000*750 | 1800*1000*1100 |

Dimensions of Working Platform(mm) | 560*550*950 | |

Power Supply | 3-Phase AC 380V, 50Hz | |

Power(kW) | 9 | 12 |

Weight(kg) | 5500 | 7500 |